So, you’re cruising down the road, feeling like a modern-day charioteer, when suddenly your car’s ABS light decides to join the party. Ah, the joys of modern technology! But fear not, fellow speed demons, for I’ve got the inside scoop on the fastest way to test that pesky wheel speed sensor. No need to break out the ancient scrolls of car manuals or sacrifice a goat to the automotive gods – I’ve got you covered.

Required Materials and Tools

In my quest to decode the mysteries of wheel speed sensors, I’ve discovered that we need to gather a few items before we can dive headfirst into the testing process.

List of Materials

- Rubbing Alcohol: Not for drinking or dancing but for cleaning purposes!

- Paper Towels: Perfect for fancy cleaning techniques.

- Wheel Speed Sensor: Makes sense to test this when you’re talking about it, right?

- Wire Brushes: No, not for your hair; we’re cleaning sensors here, not styling.

- Multimeter: Your new best friend for this testing adventure.

- Jack and Jack Stands: To give your car a little lift, not to make it tap dance.

- Safety Glasses: Because superhero vision is cool but safety first!

- Gloves: Protect those delicate hands from getting too dirty.

- Ratchet and Socket Set: For all the tightening and loosening action.

- Flashlight: Shed some light on the situation, literally.

Preparing for the Test

Before diving into testing the wheel speed sensor, let’s ensure we are well-prepared. The right setup can make the process a breeze. Here’s how to get ready for the test:

Accessing the Wheel Speed Sensor

- Locate the Sensor: Typically, the wheel speed sensor is near the brake rotor, attached to the hub assembly. It might require removing the wheel and possibly the brake caliper to access it.

- Clear the Area: Make sure the area around the sensor is clean. Dirt and debris can interfere with the testing process. A quick brush-off might be all you need.

- Use Proper Tools: Keep your trusty multimeter handy. If you need to remove components to reach the sensor, ensure you have the necessary tools like a ratchet and socket set, jack, and jack stands for safety.

- Protect Your Eyes and Hands: Safety first! Wear those stylish safety glasses and gloves to shield yourself from any unexpected surprises.

- Stability Matters: When using a jack and jack stands to lift the vehicle, make sure it’s on a stable surface. No wobbling allowed – we’re testing the sensor, not our balancing skills!

Testing the Wheel Speed Sensor Using a Multimeter

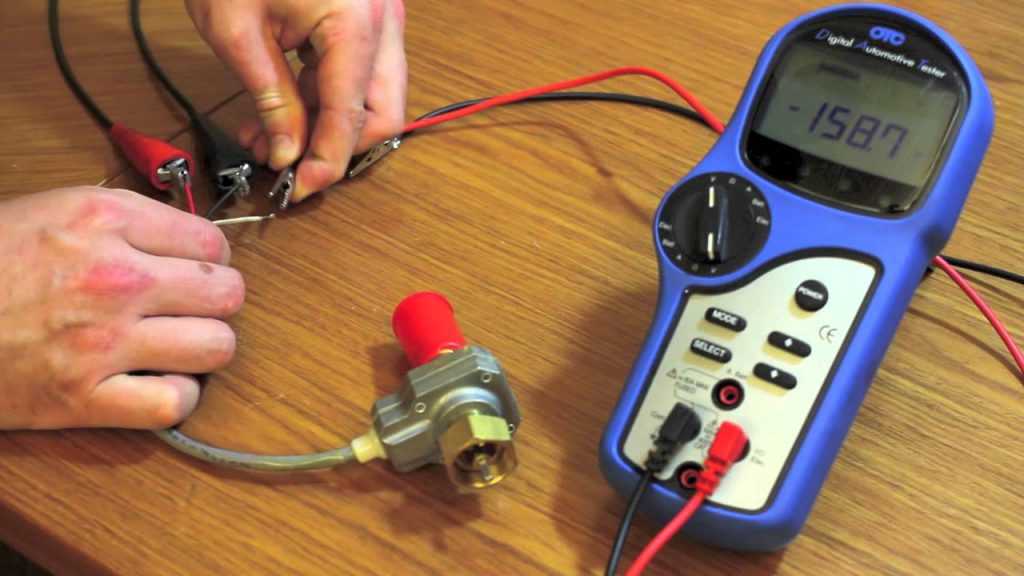

When it comes to testing the wheel speed sensor using a multimeter, I’ll guide you through the process step-by-step to ensure a smooth and effective evaluation.

Setting Up the Multimeter

- Select the Correct Settings: Before starting, ensure your multimeter is set to measure voltage and resistance accurately. Typically, you’ll need to set it to Volts DC and Ohms.

- Prepare the Sensor Connection: Locate the wheel speed sensor and disconnect it from the wiring harness. Make sure to clean the sensor’s terminals for accurate readings.

- Connecting the Multimeter: Attach the multimeter’s positive lead (red) to the sensor’s positive terminal and the negative lead (black) to the negative terminal.

Conducting the Test

- Wheel Rotation: Have someone rotate the wheel slowly while you observe the multimeter readings. The voltage should fluctuate as the wheel moves.

- Static Test: Keep the wheel still and check for resistance values. A stable reading indicates the sensor is functioning correctly.

- Comparing Readings: Compare the obtained values with manufacturer specifications to determine if the sensor is within the acceptable range.

- Voltage Check: If the voltage readings do not vary with wheel rotation, it may indicate a faulty sensor that needs replacement.

- Resistance Values: An unusually high or low resistance reading could also indicate a malfunctioning sensor.

- Consulting Manufacturer Guidelines: Refer to the vehicle’s manual or the manufacturer’s specifications for the exact values expected during the test.

Now you’re equipped to efficiently test the wheel speed sensor using a multimeter. Remember, accuracy is key, so ensure each step is performed diligently for precise results.

Troubleshooting Common Issues

Ah, the joys of troubleshooting car problems—it’s like being a detective, but with a wrench and a bit less drama. Let’s jump into two common issues you might face when testing your wheel speed sensor.

Inconsistent Readings

When your multimeter starts acting like a moody teenager, giving you readings all over the place, it’s time to channel your inner Zen master and troubleshoot those inconsistent measurements. Here’s what I do:

- Check Connections: Wiggle them like you’re doing a funky dance move. Loose connections can mess with your readings.

- Inspect Wiring: Look for any frayed wires or suspicious kinks that might be disrupting the signal flow.

- Grounding Matters: Make sure your sensor and testing equipment are grounded properly. We don’t want any static interference stealing the show.

- Environmental Factors: Sometimes even your sensor needs a break from extreme temperatures or moisture. Check if the environment is playing tricks on your readings.

No Voltage Detected

When your multimeter starts whispering, “I sense no voltage here,” it’s time to roll up your sleeves and tackle this no-power dilemma head-on. Here’s what I suggest:

- Power Source Check: Confirm that the power source supplying the wheel speed sensor is indeed operational. No juice, no readings!

- Fuse Inspection: Take a peek at the fuse box and see if any fuse related to the sensor has bid you farewell.

- Sensor Integrity: Ensure the sensor itself is in tiptop shape. A malfunctioning sensor might be the culprit behind the mysterious absence of voltage.

- Electrical System Scan: Consider checking the overall health of your car’s electrical system. It’s like giving your ride a full-body checkup to uncover any hidden issues.

Conclusion

Well, folks, testing your wheel speed sensor doesn’t have to be a drag. With the right tools and a bit of know-how, you can troubleshoot like a pro and get to the bottom of those pesky ABS light mysteries. Remember, it’s all about being thorough and checking those connections like a detective on a mission. So, next time your ABS light decides to play games, you’ll be armed and ready to show it who’s boss. Happy testing, and may your wheel speed sensor adventures be swift and successful!

Frequently Asked Questions

How do you troubleshoot the ABS light coming on in a car?

Inspect connections, wiring, and fuses. Check for proper grounding and power sources. Ensure sensor integrity and scan the electrical system for issues.

How can you efficiently test a wheel speed sensor without specialized equipment?

Turn the wheel at 1r/s and measure output voltage with a multimeter. Front wheel should be 190 – 1140mV, rear wheel higher than 650mV to confirm proper function.

What are common signs of a bad wheel speed sensor?

Inconsistent readings, no voltage detected, or ABS light illumination are common indicators of a faulty wheel speed sensor.

How important is thorough troubleshooting in testing wheel speed sensor issues?

Thorough troubleshooting is crucial to ensure accurate results, identify sensor malfunctions, and effectively resolve any problems that may arise during the testing process.